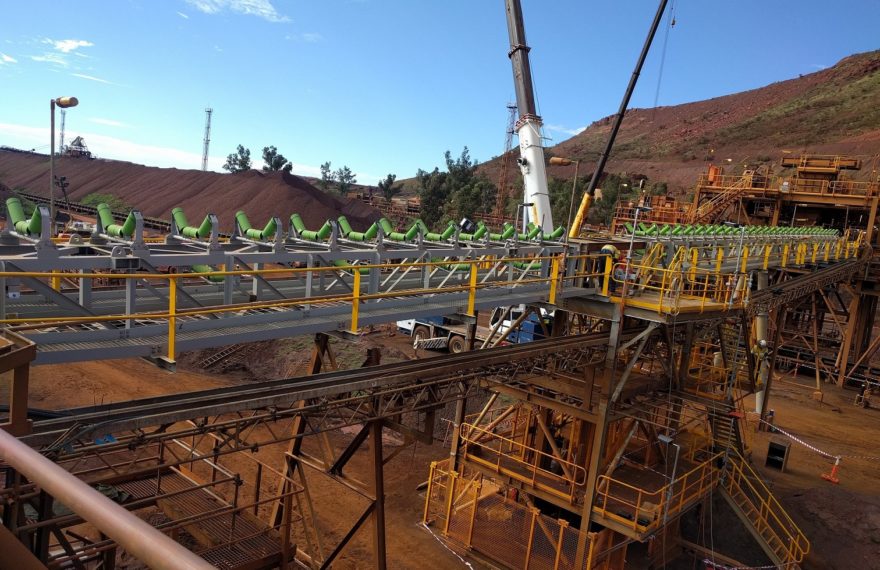

Composite Conveyor Rollers

Composite Conveyor Rollers: High performance and durability at up to 60% less weight than steel rollers.

Lorbrand Australia Composite Conveyor Rollers are available in a range of materials including GFHDPE, DUAL LAYER GFHDPE, CF-HDPE, UHMWPE, ECO-HDPE, FLAME RESISTANT and FRAS material approved for use in underground* applications.

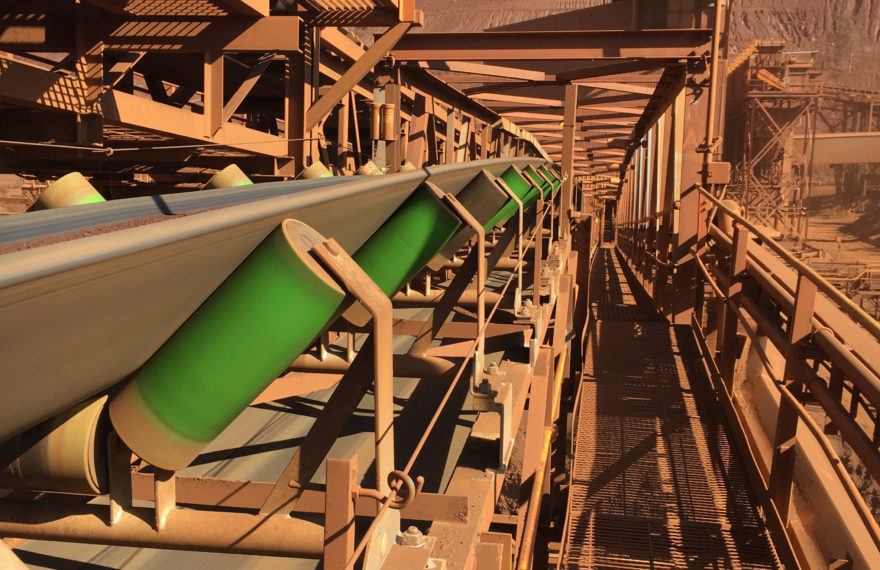

Unlike our competitors rollers which use press in end caps, our Composite Rollers have a friction welded end cap. The friction welding process binds the housing to the shell, effectively welding the shell together, increasing the structural integrity of the conveyor roller and eliminating a common failure point on existing composite conveyor rollers in the market today.

Lorbrand Australia Composite Conveyor Rollers are the only conveyor rollers manufactured globally where the tube is designed and manufactured in house, including our dual layer tube which is manufactured using a unique extrusion process. Our tube is purpose designed and manufactured solely for the use in conveyor rollers.

Composite Conveyor Roller Key Features

- Friction Welded End Caps

- Bearings range from 6205 – 6312

- Hollow shaft options for rollers with face lengths of 600mm+

- Complete range of roller sizes from 89-250mm in diameter

- Energy efficient (low breakaway mass & running friction)

- High quality 2RS or 2ZZ bearings

- Exceptional balance – ISO21940 G16

- Range of composite materials to suit a range of applications.

- Low noise Manufactured in accordance with ISO9001 and CEMA specifications

Operational Benefits

- Up to five times longer operational life over steel rolls.

- Substantial reduction in system power requirements.

- Ave 10dB drop in sound emissions over steel rolls.

- Longevity of composite rolls will dramatically improve conveyor uptime and productivity.

- Smart component configuration has improved overall operational performance over competitor conveyor rolls.

Financial Benefits

- Reduction in work related injuries, cost of spares, conveyor damage and downtime.

- Electricity usage savings.

- Reduction in noise violations.

For further information download our product brochure – Composite Conveyor Rollers or Idler Selection Chart